Glass forming

Applying our core technology, we manufacture formed glass products.

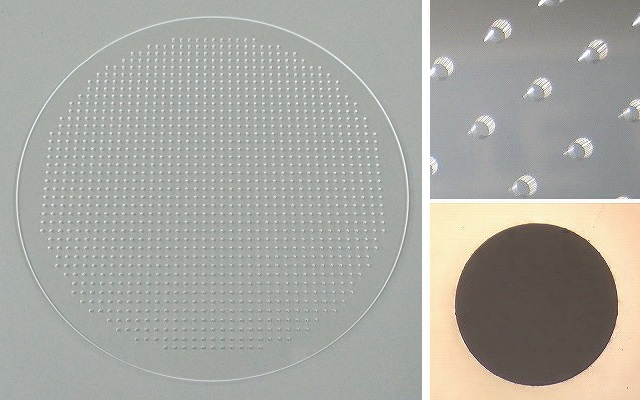

Perforated glass wafers

We make holes in glass wafers using our unique method.

The features are

- Less chipping

- Straight hole (no narrow in the middle like sandblasting)

- The periphery of the hole is also flat (the swelling around the hole like laser drilling does not occur)

- Optical polishing level finish that can be anodized to a silicon wafer.

Outline of specifications

- Glass wafer size: 3, 4, 5 and 6 inches

- Glass wafer thickness: 0.5 to 2 mm

- Hole diameter: Φ0.5 to 1.2mm

- Material: Borosilicate glass

The above specifications are just a guide.

Please tell us your request.

We will work together to realize it.

Product example

> There is no chipping around the holes in a glass wafer.

> This wafer with holes is used as glass base for sensing chip of pressure sensors.

* Preparation of dedicated and wafer specific tool / jig is required.

* Preparation of dedicated and wafer specific tool / jig is required.

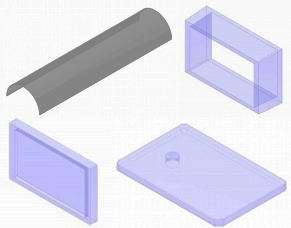

Lens forming

- Applying the technology of manufacturing caps with lenses, the glass material is heated under specific conditions and finished in the required shape.

- Glass lens does not deteriorate due to the heat generated by the light emitting element, and is also excellent in environmental resistance.

- We will work together to meet the needs of our customers.

Miscellaneous

Glass is heated to form miscellaneous shapes.

Continuous belt furnace is favor to volume production.

We also support small quantity production as well.

Please feel free to contact us.

- Smoothing the cut end face of glass

- Finishing to a certain thickness.

- Finishing in a specific shape

- Other glass forming